HexTow® AS4 carbon fiber is a continuous, high strength, high strain, PAN based fiber available in 3,000 (3K), 6,000 (6K) and 12,000 (12K) filament count tows. This allows customers to call out an industry standard, aerospace grade carbon fiber without the need to write and maintain their own specification.

What is the strongest carbon fiber weave?

A unidirectional weave creates a carbon fiber sheet that’s very strong in the direction of the fibers, but weak in the opposite direction. Plain and twill weaves, on the other hand, have more uniform strength since they’re strongest at the points where the fibers cross in either direction.

What company makes the most carbon fiber?

Hexcel Hexcel is the leading manufacturer of carbon fiber with more than 50 years of experience and the most qualified positions on aerospace programs.

What is Toray T700 carbon Fibre?

T700 carbon fiber is a high tensile strength material that can be used singly as a material to make into products. Because T700 is very flexible, it can greatly reduce the probability of cracking and cracking of the produced carbon fiber products. Therefore, the T700 material is deeply loved by FPV drone enthusiasts.

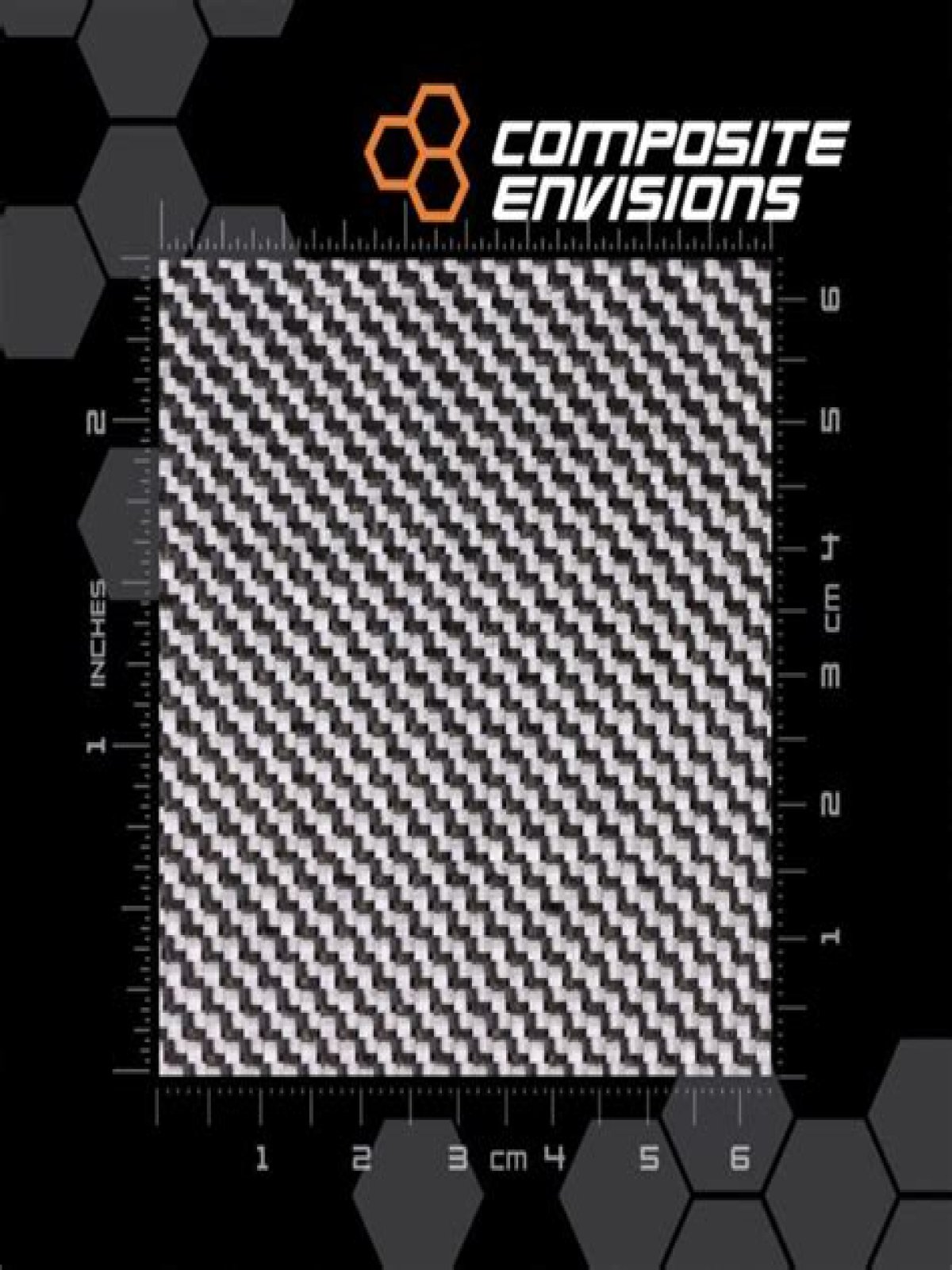

What type of carbon fiber is best?

4×4 Twill. 2×2 Twill is likely the most recognizable carbon fiber weave in the industry. It is used in many cosmetic and decorative applications, but also has great functionality, it has both moderate formability and moderate stability.

Why is carbon fiber so expensive?

Another carbon fiber cost factor is energy. It takes a lot of energy to reinforce each fiber with carbon atoms. Energy, also required to bundle the carbon together into fibers and threads. Energy costs are probably the most expensive factor in carbon fiber manufacturing.

Where is carbon fiber made?

Carbon fiber is made from organic polymers, which consist of long strings of molecules held together by carbon atoms. Most carbon fibers (about 90%) are made from the polyacrylonitrile (PAN) process. A small amount (about 10%) are manufactured from rayon or the petroleum pitch process.

Is carbon fiber manufactured in India?

New Delhi:Reliance Industries is investing in setting up India’s first carbon fibre manufacturing unit to cater to aerospace and defence needs, the company said in its annual report.

How much does carbon fiber cost per kg?

The cost of CF is directly related to the yield and cost of the precursor from which it is obtained. At present, the PAN-based carbon fibers and their average cost of non-aerospace grade are around USD 21.5 per kg, with a conversion efficiency of only 50%.

Is T800 better than T700?

In short, T800 carbon is stronger and lighter and 11% stronger than T700 in terms of tensile strength – the load a mast is under when elongated/flexing. It also delivers a swifter return response reaction. T800 is also slightly stronger than T700 in terms of compressive strength too.

Where is Toray carbon made?

We manufacture carbon fiber globally in Japan, Korea, France, Hungary, Mexico and the USA, ensuring a stable supply and responsive deliveries based on local operations.