The three types of strain gage configurations, quarter-, half-, and full-bridge, are determined by the number of active elements in the Wheatstone bridge, the orientation of the strain gages, and the type of strain being measured.

- How do I know what strain gauge I have?

- How many strain gauges are there?

- What can you measure with a strain gauge?

- What are the most important types of strain gauge?

- What is mechanical strain gauge?

- Which type of strain gauge is the most sensitive and reliable?

- Can strain gauges measure compression?

- Are strain gauges reusable?

- How is a strain gauge noisy late and wrong?

- How accurate are strain gauges?

- Are strain gauges linear?

- What is sensitivity of strain gauge?

- What are the advantages and disadvantages of strain gauge?

- Are strain gauges piezoelectric?

- Why are strain gauges so common?

- Is strain gauge an active transducer?

- How does a strain gauge transducer work?

- Can strain gauge measure displacement?

- What is the uncertainty of a strain gauge?

- Are strain gauges wrong?

How do I know what strain gauge I have?

During a given test, a gauge is attached to the specimen by an adhesive bond. As the specimen is deformed by loading, the foil within the gauge is deformed, which causes the electrical resistance to change.

How many strain gauges are there?

There are two types of strains they are positive strain and negative strain. Suppose we are using the one electrical conductor or electrical wire in a strain gauge which can pass the electricity through it.

What can you measure with a strain gauge?

A strain gauge is a type of electrical sensor. It’s primary use is to measure force or strain. The resistance of a strain gauge changes when force is applied and this change will give a different electrical output. Strain gauges use this method to measure pressure, force, weight and tension.What are the most important types of strain gauge?

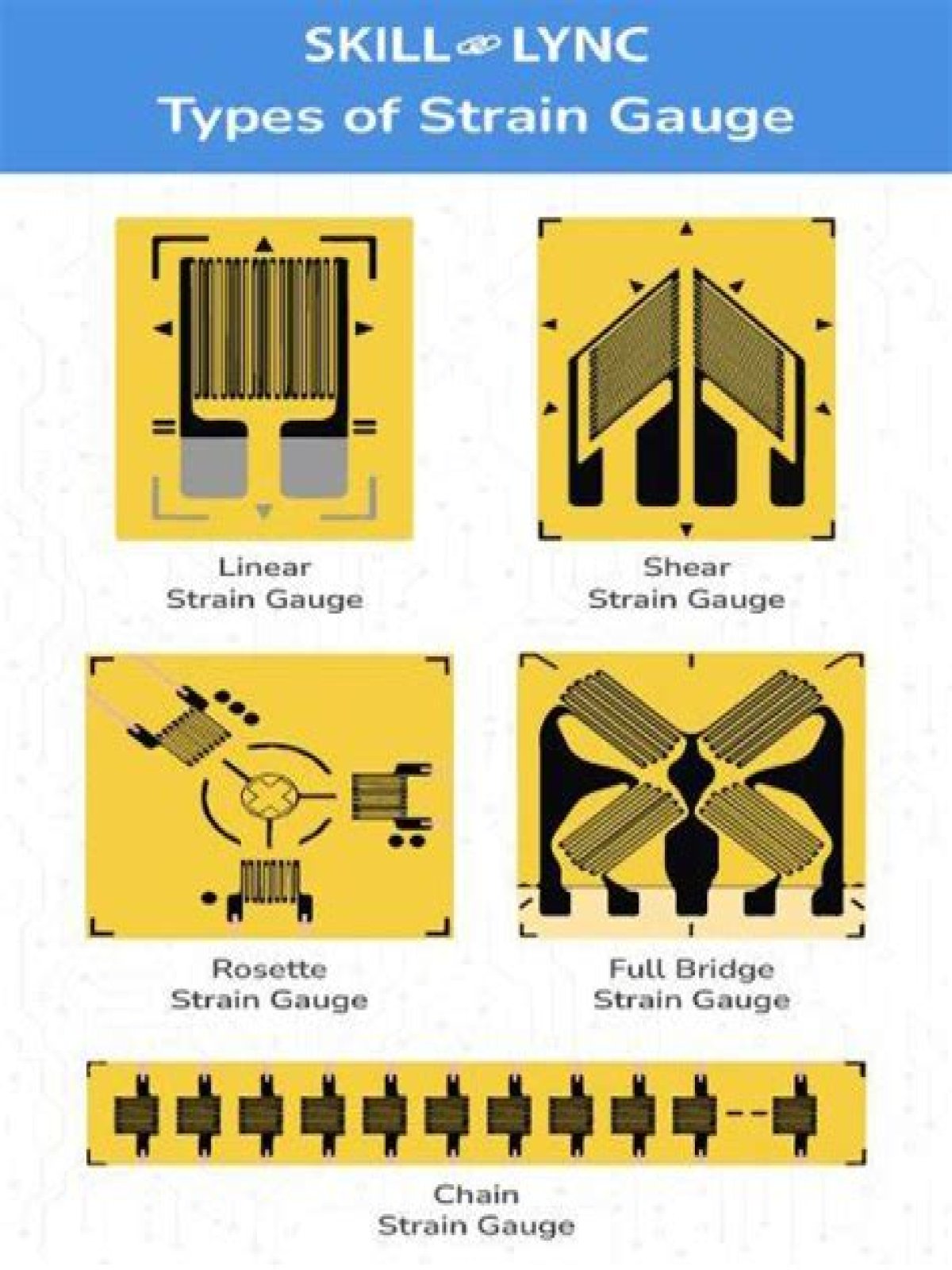

- Linear strain gauges.

- Membrane Rosette strain gauges.

- Double linear strain gauges.

- Full bridge strain gauges.

- Shear strain gauges.

- Half bridge strain gauges.

- Column strain gauges.

- 45°-Rosette (3 measuring directions)

What is mechanical strain gauge?

Used to determine the strain (length changes) in concrete specimens and structures, rock strata, different parts of a structure, in remote areas and under adverse conditions, using a single instrument. The instrument can also be used for other structures like steel and wood. …

Which type of strain gauge is the most sensitive and reliable?

Typical foil strain gauge; the blue region is conductive and resistance is measured from one large blue pad to the other. The gauge is far more sensitive to strain in the vertical direction than in the horizontal direction.

Can strain gauges measure compression?

As a technical term “strain” consists of tensile and compressive strain, distinguished by a positive or negative sign. Thus, strain gauges can be used to pick up expansion as well as contraction.Are strain gauges reusable?

Are strain gauges reusable? The main advantages of mechanical strain gauges are the ease with which they can be used, their relatively low cost and the fact that they are reusable.

How does strain gauge measure stress?The material stress may only be calculated from equation σ = E ε, if the elongation in the force direction has been measured and the stress state is single-axis. In the transverse direction, a strain is measured, although there is no mechanical stress.

Article first time published onHow is a strain gauge noisy late and wrong?

Another often-overlooked source of noise is leakage to ground through the strain gage and/or the cabling. If excessive, this leakage can cause noise transfer from the specimen to the gage circuit, since even supposedly well-grounded specimens may carry some noise.

How accurate are strain gauges?

Strain meters/ digitizers have typical resolution/ precision of about ±1 x 10^-6 mm/mm (±0.0005 mV/V bridge output). Thus using four active gauges (‘arms’) provides benefits in precision (and accuracy) when measuring small strains.

Are strain gauges linear?

Geometry of the Strain Gauge Linear strain gauges (e.g. LY4) have one measuring grid and measure the strain in one direction. Linear strain gauges (e.g. LY4) have one measuring grid and measure the strain in one direction. Linear strain gauges (e.g. LY4) have one measuring grid and measure the strain in one direction.

What is sensitivity of strain gauge?

The strain sensitivity k of a strain gauge is the proportionality factor between the relative change in resistance ΔR/R0 and the strain ε to be measured: ΔR/R0 =k⋅ε. The strain sensitivity yields a dimensionless number and is designated as the gauge factor.

What are the advantages and disadvantages of strain gauge?

In the strain gauge you will find no moving parts. Strain gauge are usually small so these are easy to handle. Disadvantages: strain gauges biggest disadvantage is that they are non-linear.

Are strain gauges piezoelectric?

Because of this, manufacturers use various compensation techniques: strain gauge sensors use self-temperature compensating gauges; piezoelectric sensors adjust for temperature effects with a charge amplifier.

Why are strain gauges so common?

Strain gauges are devices that are commonly used by engineers to measure the effect of external forces on an object. They measure strain directly, which can be used to indirectly determine stress, torque, pressure, deflection, and many other measurements.

Is strain gauge an active transducer?

Strain Gauge is a passive transducer that converts a mechanical elongation or displacement produced due to a force into its corresponding change in resistance R, inductance L, or capacitance C. It uses the variation in electrical resistance in wires to sense the strain produced by a force on the wires.

How does a strain gauge transducer work?

Strain gauge-type transducers electrically convert physical quantities. They operate by converting physical quantities into mechanical stress in a component called a sensing element, and then electrically converting that stress with a strain gauge.

Can strain gauge measure displacement?

A strain gauge based displacement transducer for measurement of the displacement in the range of 0 to 10 mm is reported. As compared to LVDT this transducer has short body length and is free from electromagnetic effect. this transducer has short body length and is free from electromagnetic effect.

What is the uncertainty of a strain gauge?

The Gauge Factor This factor describes the correlation between the change in strain and the change in relative resistance. It has been determined experimentally by the manufacturer. The uncertainty of the gauge factor is generally 1%.

Are strain gauges wrong?

The strain gage can become ustable if too much excitation voltage is applied given the heat sink capability of the material to which the strain gage is bonded. As a result of these, a certain amount of error and uncertainty can be introduced at the very beginning of the measurement process.